Volkswagen Golf Service & Repair Manual: Adhesion promoter

| Adhesion promoter -LLS MAX 015- for plastics |

| The adhesion promoter -LLS MAX 015- is a versatile

single-pack product suitable for all plastic parts commonly

found on vehicle exteriors. |

| All plastic parts commonly found on vehicle exteriors (PP,

EPDM, ABS, PC, PPO, PA, R-TPU, PBTP, PVC, PUR, PUR flexible

foam, UP-GF). |

|

|

|

| The substrate must be free of release agents. |

| Before cleaning plastic parts, temper them for 60 minutes at

+60 °C to “sweat out” the release agents. |

| – |

Clean with anti-static plastic cleaner -LVM 001 001 A2- or

with the milder slow-drying silicone remover -LVM 020 100 A5-. |

Note Note

| The effort required for the necessary cleaning depends on

the type and quantity of the release agent used. It is

recommended to use an emery pad to help in cleaning. |

| Let the thinner evaporate completely (e.g. air-dry overnight

at ambient temperature or for 30-40 minutes at +60 °C). |

|

|

|

| – |

Before priming, clean lightly once more with anti-static

plastic cleaner -LVM 001 001 A2- or slow-drying silicone remover

-LVM 020 100 A5- (with anti-static effect). |

|

|

|

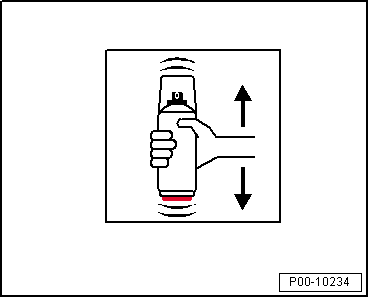

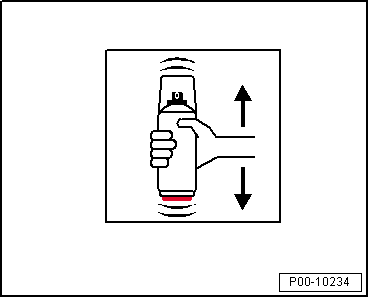

| – |

Vigorously shake can for at least 2 minutes. |

|

|

|

| Method of application: “spray”. |

| – |

Apply one full coat (1-2 µm). |

| – |

Maintain a distance of 20-25 cm. |

|

|

|

| VOC content:

2004/42/IIB(e)(840)730 |

The EU limit value for this

product (product category IIB.e) in ready-to-spray form is max. 840 g/l

of volatile organic compounds. The VOC content of this product in

ready-to-spray form is max. 730 g/l. |

| The guaranteed shelf life is 60 months from date of

production. May be used until the date stated on the label at

latest if stored in sealed original containers at +20 °C. |

|

|

|

| The recommended storage temperature for this product is

+20 °C to +25 °C (the temperature must not be below +5 °C). |

|

|

|

Designation:

Blender -LLS MAX 009-

Issued 10.2008

Product description

The blende ...

Other materials:

Introduction

This chapter contains information on the following subjects:

→ Warning lamp and coolant temperature display

→ Coolant specification

→ Checking the coolant level and refilling coolant

Never carry out any work on the engine coolant system if you are not famili ...

Masking areas, front body

Masking areas, plenum chamber

A -

No sealant on threads or contact surfaces.

C -

No cathodic dip primer, surfacer or top coat on threads or contact

surfaces.

D -

Threads free of surfacer and top-coat pa ...

Overview of fitting locations – adaptive cruise control, variant 2

1 -

Dash panel insert -KX2-

With control unit in dash panel insert -J285-.

Removing and installing

→ Chapter

2 -

Front bumper carrier

3 -

Retaining plate

...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Note

Note Blender

Blender

Caution

Caution