Volkswagen Golf Service & Repair Manual: Checking pistons and cylinder bores

| – |

Using a micrometre, measure approx. 10 mm from the lower

edge, perpendicular to the piston pin axis. |

| Maximum deviation from nominal dimension: 0.04 mm |

|

|

|

|

Piston diameter mm |

|

Specification |

74.42

1) |

| 1) Dimensions without coating |

| Piston manufacturer Federal Mogul (thickness of 0.018 mm per

side) |

| Piston manufacturer Mahle (thickness of 0.015 mm per side) |

|

| Measuring piston ring gap |

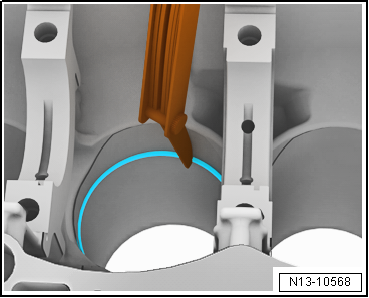

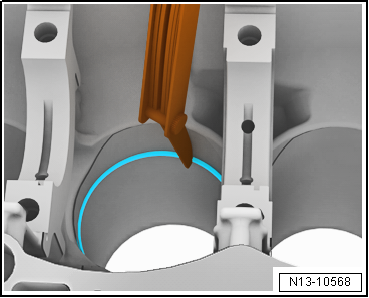

| – |

Push piston ring at right angles to cylinder wall from above

down into cylinder bore to approx. 15 mm from bottom end of

cylinder. |

| – |

Push in using a piston without piston rings. |

|

|

|

| Piston

ring |

New

mm |

Wear

limit

mm |

| Compression

ring |

0.20

+ 0.15 |

1.0 |

| Oil scraper ring (2

parts) |

0.20

+ 0.20 |

3.0 |

| Oil scraper ring

(3 parts) |

0.50

+/- 0.25 |

3.0 |

| Measuring ring-to-groove clearance |

| – |

Clean annular groove of piston before check. |

|

|

|

| Piston ring |

New

mm |

Wear limit

mm |

| 1st compression ring

(piston ring manufacturer Federal Mogul) |

0.050 … 0.090 |

0.15 |

| 1st compression ring

(piston ring manufacturer Mahle) |

0.035 … 0.085 |

0.15 |

| 2nd compression ring |

0.030 … 0.070 |

0.15 |

| Oil scraper rings (3

parts) |

Not

measurable |

| Oil scraper rings (2 parts) |

0.04 … 0.08 |

Risk of damage to the surface of the cylinder bore caused by incorrect

machining.Do not machine cylinder bore (reboring, honing, grinding) with

workshop equipment.

| – |

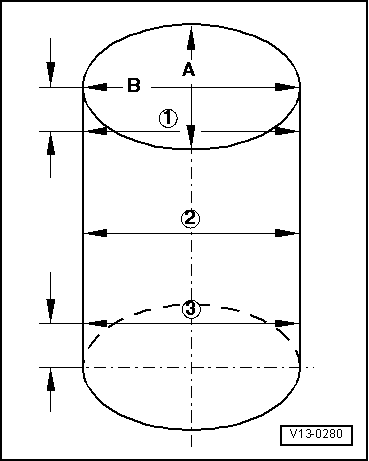

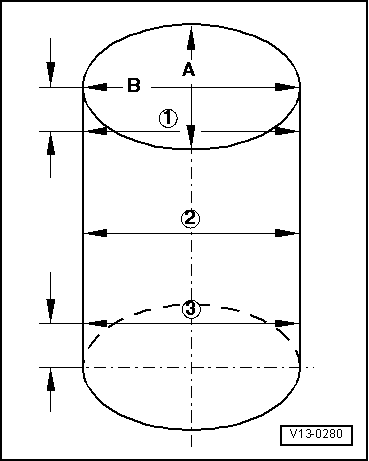

Using cylinder gauge -VAS 6078- take measurements at 3

positions diagonally in lateral direction

-A- and longitudinal direction -B-. |

| Maximum deviation from nominal dimension: 0.08 mm |

|

|

|

|

Cylinder bore diameter mm |

| Specification |

74.5 + 0.015

1)

+0.005 |

Note Note

| Cylinder bores must not be measured when cylinder block is

mounted on engine and gearbox support -VAS 6095-, as

measurements may be incorrect. |

|

|

|

Special tools and workshop equipment

required

Socket -T10545-

Removing

–

Remove noi ...

Special tools and workshop equipment

required

Plastigage

Procedure

–

Remove conrod ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Removing and installing oil spray jets

Removing and installing oil spray jets Checking radial clearance of conrods

Checking radial clearance of conrods