Volkswagen Golf Service & Repair Manual: 1-pack fill clean spray can -LLS MAX 112-, Aqua Premium system

| 1-pack fill clean spray can -LLS MAX 112-, 400 ml for

water-based mixing paint “Aquaplus premium system” |

| The product is an aerosol can, pre-filled with solvents and

propellant, and especially designed for use with the “Aquaplus

System” and the “Aqua Premium system”. |

| For filling the aerosol can, only the special FillClean

equipment may be used. |

| Field of application: Clever Repair only. |

| The product is an aerosol can, pre-filled with solvents and

propellant, and especially designed for use with the “Aquaplus

System” and the “Aqua Premium system”. |

| The aerosol can does not contain any paint when delivered.

It is a semi-finished product. |

| The ready-to-use end product is produced through filling the

pre-filled aerosol can with 100 ml of undiluted Aquaplus or Aqua

Premium basecoat using the special FillClean equipment. |

| The ready-to-use (filled with paint) aerosol must always be

labelled accordingly, prior to further use. For this purpose, a

special label indicating the respective colour, generated and

printed by the tinting system, can be used. |

| It is essential to ensure that all the data given in the

example below is present on this label. |

| Indicating content and and pre-filling |

| The content of 316 ml (0.32 l) declarated on the label

refers to the final product (after filling with paint). |

| The aerosol can, pre-filled with 294 ml propellant and

solvents, is filled with additional 100 ml of ready-to-use Aqua

Premium basecoat, incl. additive for Aqua Premium -LVM 035 200-

or additive for Aqua Premium -LVM 035 301-. |

Note Note

| Protective garments and equipment in accordance with work

safety regulations must be worn. |

| Set up the FillClean equipment in a well ventilated room. |

| The maximum capacity of the aerosol can must not be exceeded

when filling. Risk of explosion! |

| No poisonous carcinogenic substances or halocarbons must be

used for filling the aerosol cans. |

| Warning: electrostatic discharge! Only use a damp cloth for

cleaning of plastic parts. |

| Any repairs must be performed by a qualified technician. |

| Paint residues must be removed from the machine at regular

intervals. Use a cloth and an appropriate solvent for this

purpose. |

| The pressure supply line must be checked at regular

intervals. |

| Mixing instructions for “Aqua Premium system” |

|

|

|

| Mixing containers: |

Plastic containers or tinplate

containers with inner coating |

| Sieves: |

Waterproof-glued or waterproof

125 μm strainers |

| Additive: |

Additive for Aqua-Premium -LVM

035 200/300/301- (at normal or high temperatures and low humidity

depending on size of object) |

| Pot life: |

Should be processed within 24

hours after adding the additive for Aqua-Premium LVM 035 200/301, if

possible. |

| Additive at 20 °C material

temperature: |

20 % Additive for Aqua

premium -LVM 035 200/300/301- |

| Special notes: |

Recommendation for solid

colours: for optimum application behaviour it is recommended to always

use additive for Aqua Premium -LVM 035 301-. |

| FillClean filling process |

| Observe the operating instructions of the filling equipment. |

|

|

|

| – |

Put filling pad on indenter. |

|

|

|

| – |

Fit FillClean filling cylinder onto spray can. |

|

|

|

| – |

Fit and push down the FillClean cap. |

|

|

|

| – |

Set FillClean can and filled cylinder into upper groove

-1- of the FillClean machine. |

Note Note

| When the FillClean can is inserted into the upper groove

-1-, the lower rotating plate

-2- must first be positioned at the

very bottom. As soon as the FillClean can has been inserted into

the upper groove -1-, turn the

rotating plate -2- upwards to use

it as a counterhold. |

|

|

|

| – |

Push the button to the right to trigger filling. Wait

approx. 10 seconds. |

|

|

|

| – |

After filling, remove filling cylinder

-2- from FillClean can. |

| – |

Remove FillClean cap -1- from

filling cylinder -2-. |

| – |

Fit spray nozzle -3- onto

FillClean can. |

|

|

|

| – |

Leave the pad in the cap to indicate the filled colour tone. |

| – |

The FillClean can is now ready to use. |

| 1-pack wash primer -LVM 044 007 A2-/-LVM 044 171 A2- |

| 2-pack plastic adhesion surfacer -LKF 696 009 A2-/-LKF 696

040 A2- |

| For plastic surfaces, refer to

→ Remark. |

|

|

|

| – |

Thoroughly clean factory or old paintwork and/or 2-pack HS

surfacer using silicone remover -LSW 019 000 A5-. If severely

soiled, pre-clean with slow-drying silicone remover -LVM 020 100

A5-. |

|

|

|

| – |

Dry-sand using orbital sander with P500-grain sandpaper and

dust collector. |

|

|

|

| – |

Wet-sand with P800 to P1000-grain sandpaper. |

|

|

|

| – |

Before recoating the sanded substrates, thoroughly clean

them of dust, sanding residue and other dirt using silicone

remover -LSW 019 000 A5-. |

| Wipe off any excess silicone remover with a lint-free cloth,

leaving no streaks. Observe technical data sheet

→ Chapter „Silicone remover“. |

| Areas sanded to bare metal must be primed with 1-pack wash

primer -LVM 044 007 A2-/-LVM 044 171 A2-. |

| Bare metal spots must not be larger than 5.0 cm in diameter. |

| If 2-pack HS surfacer is used, bare metal spots must be

primed using 2-pack wash primer -LHV 043 000 A2- or 1-pack wash

primer -LVM 044 007 A2-/-LVM 044 171 A2-. |

| It is recommended to test the colour tone on a spray sample

prior to application. |

|

|

|

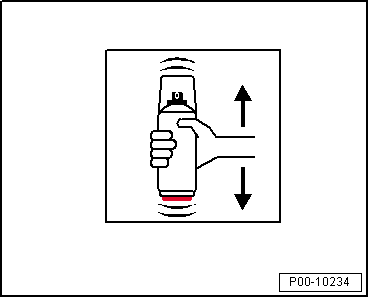

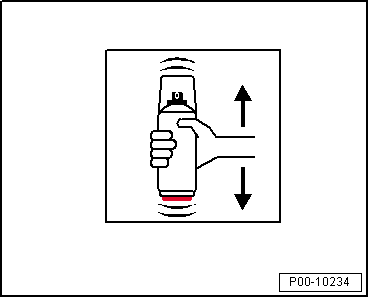

| – |

Shake aerosol well (at least 2 minutes) to ensure proper

mixing. |

|

|

|

| Method of application: “spray”. |

| – |

Maintain a distance of 20-25 cm. |

| – |

The specified thickness for the dry film is 15-20 µm. |

|

|

|

| – |

Apply in 2 spray passes (1 normal coat followed by 1 finish

coat) with 5-10 minutes intermediate flash-off time. |

| – |

The specified thickness for the dry film is approx. 15 to

20 µm. |

Note Note

| With low opacity colours, it may be necessary to apply an

additional spray cote (wet-on-wet). |

| As an alternative, wait until the paint film appears matt

prior to the application of the additional spray coat. |

| To prevent clogging of the nozzle, after each use (or any

interruption of the spray operation), hold the can upside down

and press the spray button until the material flow stops (i.e.

until the valve is empty). |

|

|

|

| The drying time/flash-off time for clear coat application is

15 to 30 minutes at +20°C. Important note: Observe flash-off

time (coated surface must appear matt). |

| 2-pack HS clear coat (see relevant data sheet). |

| 2-pack clear coat -LLS MAX 210- (also recoatable with other

2-pack HS clear coats). |

Caution

Caution

| Protective garments and equipment in accordance with

work safety regulations must be worn. |

| Observe safety information sheets as well as

warnings on the label of the spray can. |

| After filling the can, shake it for approx

2 minutes. |

| Before applying, shake can for approx 2 minutes. |

| Shake again briefly before spraying each coat. |

| After fully emptying the spray can, dispose of as

recycling material |

|

|

|

|

| VOC content:

2004/42/IIB(e)(840)690 |

The EU limit value for this

product (product category IIB.b) in ready-to-spray form is max. 840 g/l

of volatile organic compounds. The VOC content of this product in

ready-to-spray form is max. 690 g/l. |

| The guaranteed shelf life of pre-filled aerosol (without

paint) is 24 months. |

| After filling with paint, the shelf life of the aerosol is

1 week. |

|

|

|

Designation:

1-pack FillClean spray can -LLS MAX 099-, 250 ml for

waterborne mixing paint “Aquaplus system”

1- ...

Designation:

2-pack surfacer -LLS MAX 202 M2-, medium grey

Issued 03.2013

Product description

...

Other materials:

Assembly overview - alternator without sliding bushes

1 -

Bolt

Qty. 4

Specified torque: 23 Nm

2 -

Alternator -C-

Removing and installing

→ Chapter

Checking

→ Chapter

Removing and instal ...

Displays, warning and indicator lamps

Fig. 166 In the instrument cluster display:

ACC deactivated temporarily; vehicle detected ahead, time interval set

Fig. 167 In the instrument cluster display:

ACC active: vehicle detected ahead, time interval is being set

First read and observe the introductory information

and safety warni ...

Removing and installing tail light in rear lid

Note

Removal and installation are described for the left side.

Removal and installation on the right side are carried out in

the same way.

If the event of a defective LED, the entire tail light needs

to be rene ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Note

Note Note

Note 1-pack fill clean spray can -LLS MAX 099-, -LLS MAX 100-, Aquaplus system

1-pack fill clean spray can -LLS MAX 099-, -LLS MAX 100-, Aquaplus system 2-pack surfacer

2-pack surfacer

Caution

Caution